Building on the momentum of the hugely successful 2022 exhibition, Hillhead 2024 was the most visited edition ever in terms of the volume of visits over the three days, with visitors spending more time at the show than ever before and a record number attending for more than one day. In total there were a staggering 26,626 visits over the three days – marking an 8% increase from the 2022 edition.

In terms of unique visitors, with 19,577 attendees from 67 countries (+6.2% compared with 2022) this year’s edition had the second highest ever number of trade visitors (only 2018 was higher at 19,753, although that show had less volume over the three days). Hillhead 2024 also recorded the event’s busiest day ever in its 42-year history, with almost 10,800 visitors attending on day two of the show (Wednesday 26 June).

Put simply, there is no trade show quite like it in the world. With every square metre of exhibition space – including an extended Showground Pavilion – fully booked and occupied, and a record number of machines taking part in four live demonstration areas around the quarry, not to mention a host of site improvements (eg additional catering areas, more car parking spaces, new hydration stations etc.), Hillhead 2024 was bigger, better, and busier than ever before.

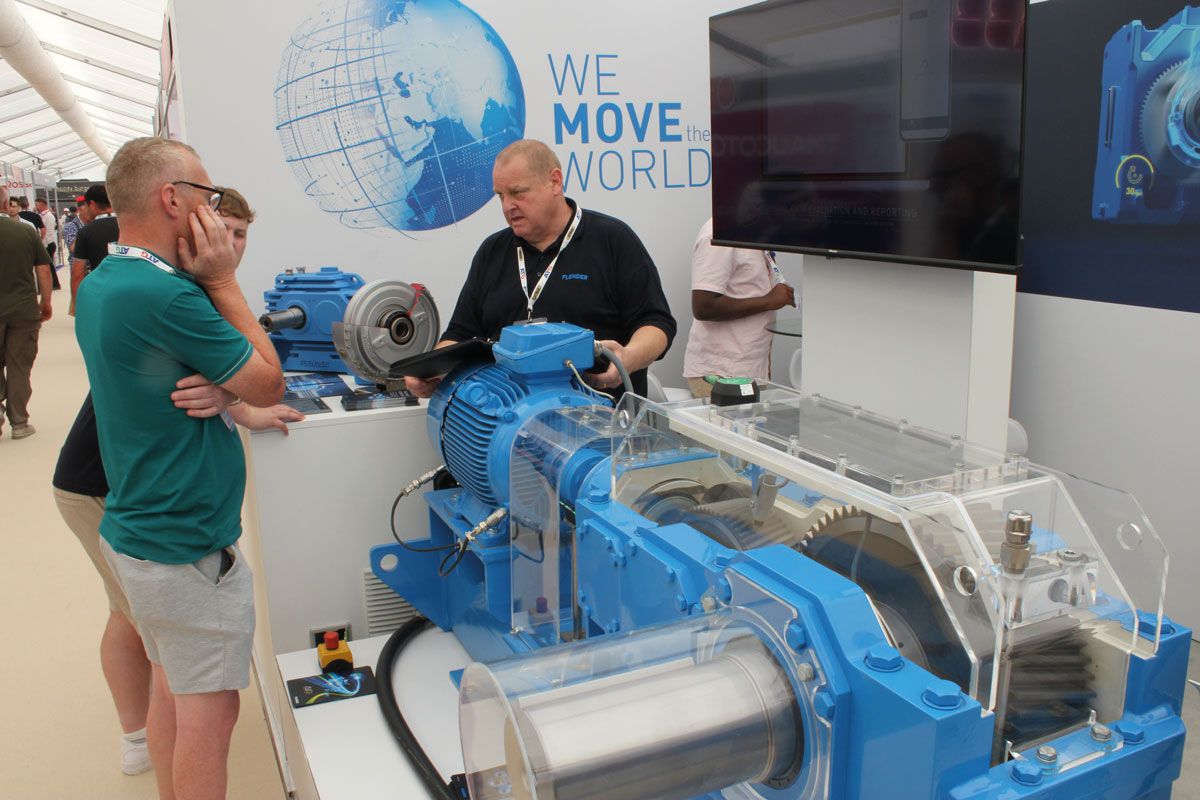

Commenting on this year’s show, event director Richard Bradbury said: ‘With the sun shining and visitors spending more time at the show than ever before, it was fantastic to see Hillhead continuing to break new attendance records. It’s an exciting time for the industry as digitalization, automation, and decarbonization continue to drive change within the quarrying, construction, and recycling sectors, and this was represented by the scale and quality of the 600 or so companies that exhibited.

‘But my abiding memory of Hillhead 2024 is of the unique ‘human’ platform it provided for buyers and sellers to engage....to feel, touch, and interact with the products on show, and, of course, to catch up with colleagues and network with the wider industry.’